Product series

Zhengzhou Bulang Machinery Technology Co., Ltd

Hotline:0371-67827320

Address:No. 18, Dongfang Road, Mazhai Economic Development Zone, Erqi District, Henan, China

Phone:13523525799

Email:

Current location:Home > Products > Mill stand >

Mill stand

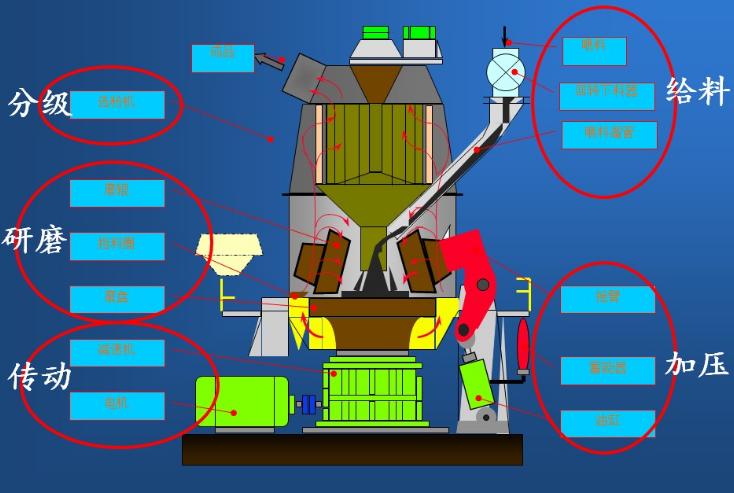

Product introduction:1、 Equipment introduction: cement vertical mill adopts a new generation of cement grinding technology, which has many advantages, such as simple production process system, low unit power consumption, stable cement product quality and convenient operation. It has developed rapidly in the field of cement clinker grinding.

1、 Equipment introduction: Cement vertical mill adopts a new generation of cement grinding technology, which has many advantages, such as simple production process system, low unit power consumption, stable cement product quality and convenient operation. It has developed rapidly in the field of cement clinker grinding. Compared with the traditional ball mill, the cement vertical mill of Bulang heavy industry can save 30% electricity per ton. At the same time, it has less auxiliary equipment, more energy for one machine, small floor area and small dust pollution. It is a new generation of new environmentally friendly cement grinding equipment, which is in line with the national energy conservation and environmental protection policy.

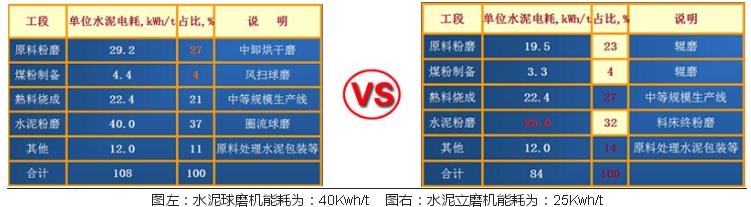

二、水(shuǐ)泥立磨與球磨機(jī)哪個(gè)好?

現以一(yī)條日産5000噸水(shuǐ)泥熟料生(shēng)産線為(wèi)例,進行比較:

It can be seen that:

1. The comprehensive power consumption of cement vertical mill is 15kwh / t lower than that of ball mill.

2. A 5000tpd cement plant can only grind clinker, and the annual energy saving is 15kwh / T × 5000t/d × 300D = 22.5 million kWh (that is, 22.5 million kwh of electricity can be saved by clinker grinding in cement plant in one year).

In addition, the vertical mill is superior to the traditional ball mill and roller press process in terms of system process, operation rate and operability. It has the advantages of simple process flow, strong adaptability to raw material moisture and hardness, low installed power per unit output, small number of electromechanical equipment and good product performance, and can meet various engineering needs.

3、 Why choose Bulang heavy industries?

1. The cement vertical mill of Bulang heavy industry introduces the Ube vertical mill technology from Japan to optimize the working mechanism of grinding roller and grinding disc, so as to ensure the perfect particle shape and stable and reliable quality of finished cement products.

2. Bulang heavy industry has a large supporting steel casting company and a large machining workshop, which can meet the casting capacity of 120t single piece. The supply of parts is complete, which greatly shortens the supply cycle of cement vertical mill. The strong production capacity of parts provides a guarantee for customers to replace spare parts in the later stage.

Technical parameters of high fine vertical mill

|

規格型号 |

産量(t/h) |

入磨物(wù)料粒度(mm) |

入磨物(wù)料水(shuǐ)分(%) |

産品細度(10-40um) |

産品水(shuǐ)分(%) |

主電(diàn)機(jī)功率(kw) |

|

JRM800X |

0.8-2.5 |

0—15 |

<10 |

97% |

≤1 |

45 |

|

JRM110X |

1.6-5 |

0—20 |

<10 |

97% |

≤1 |

90 |

|

JRM1250X |

2.2-7 |

0—20 |

<10 |

97% |

≤1 |

132 |

|

JRM1300X |

3.0-10 |

0—25 |

<10 |

97% |

≤1 |

180 |

|

JRM1500X |

4.0-14 |

0—35 |

<10 |

97% |

≤1 |

250 |

|

JRM1700X |

6.0-20 |

0—35 |

<10 |

97% |

≤1 |

355 |

|

JRM1900X |

7.5-25 |

0—40 |

<10 |

97% |

≤1 |

450 |

|

JRM2200X |

10-34 |

0—40 |

<10 |

97% |

≤1 |

600 |

|

JRM2400X |

14-45 |

0—40 |

<10 |

97% |

≤1 |

800 |

|

規格型号 |

産量(t/h) |

生(shēng)料水(shuǐ)分(%) |

産品細度 |

産品水(shuǐ)分 |

主電(diàn)機(jī)功率(kw) |

|

JRM800 |

4-7 |

≤10% |

80%通(tōng)過 |

<1 |

55 |

|

JRM1100 |

7-13 |

≤10% |

110 | ||

|

JRM1250 |

14—18 |

≤10% |

160 | ||

|

JRM1300 |

20—25 |

≤10% |

200 | ||

|

JRM1500 |

26—34 |

≤10% |

280 | ||

|

JRM1700 |

40—60 |

≤10% |

400 | ||

|

JRM1900 |

60—80 |

≤10% |

500 | ||

|

JRM2200 |

80—110 |

≤10% |

800 | ||

|

JRM2400 |

95—130 |

≤10% |

900 | ||

|

JRM2800 |

120—160 |

≤10% |

1120 |

|

規格型号 |

産量(t/h) |

原煤水(shuǐ)分(%) |

産品細度 |

煤粉水(shuǐ)分 |

主電(diàn)機(jī)功率(kw) |

|

JRM 800M |

3—5 |

≤10% |

80%通(tōng)過 |

<1 |

55 |

|

JRM110M |

6—8 |

≤12% |

110 | ||

|

JRM1250M |

9—13 |

≤15% |

132 | ||

|

JRM1300M |

15—20 |

≤15% |

160 | ||

|

JRM1500M |

18—25 |

≤15% |

250 | ||

|

JRM1700M |

22—32 |

≤15% |

315 | ||

|

JRM1900M |

35—45 |

≤15% |

400 | ||

|

JRM2200M |

40—50 |

≤15% |

500 | ||

|

JRM2400M |

50—70 |

≤15% |

630 | ||

|

JRM2800M |

70—100 |

≤15% |

800 |

JRMSpecifications and technical parameters of vertical fine grinding series of slag

|