Product series

Zhengzhou Bulang Machinery Technology Co., Ltd

Hotline:0371-67827320

Address:No. 18, Dongfang Road, Mazhai Economic Development Zone, Erqi District, Henan, China

Phone:13523525799

Email:

Current location:Home > Products > Lime equipment production line process >

Lime equipment production line process

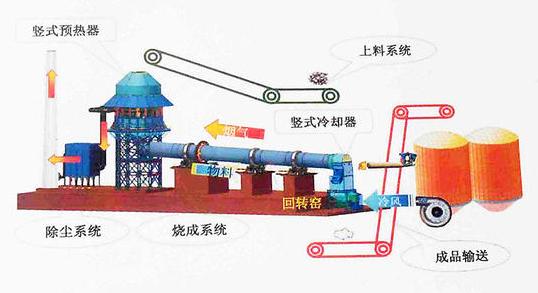

Product introduction:The specialized equipment for lime production line (active lime) is specialized in crushing and calcining and decomposing ores such as limestone and dolomite. The processing equipment includes: cooler, feeder, rotary kiln, crusher, preheater, vibrating screen, and belt conveyor or other equipment can be used for combination between the equipment. A complete set of supporting machines enter the silo from dolomite or limestone

Active lime production line [production capacity]: 150-1500t / D [lime kiln Specification]: Φ two point five × 40~ Φ 5.6x76m [introduction to production line]: active lime production line refers to the operation line for producing active lime. The specialized equipment for lime production line (active lime) is specialized in crushing and calcining and decomposing ores such as limestone and dolomite. The processing equipment includes: cooler, feeder, rotary kiln, crusher, preheater, vibrating screen, and belt conveyor or other equipment can be used for combination between the equipment. The complete set of supporting machines starts from dolomite or limestone entering the silo and forms a professional production and processing line through a series of equipment such as feeding, crushing, screening, preheating and decomposition, high-temperature burning and cooling to complete the whole process of lime calcination. Process flow of activated lime production

Advantages of active lime processing production line equipment:

The automation level of the whole production line has reached from automatic supply to the calcination of finished activated lime to realize full-automatic production. In addition to necessary maintenance and overhaul of the equipment every day, dolomite is put into the silo from the loader, and a closed-circuit crushing device is set between the vibrating screen and the crusher. The production capacity of the whole set of production line is higher than that of traditional simple equipment, and the cost of production is also low. It really achieves high income, and the composition of calcined lime calcium oxide is stable, which meets the requirements and standards of domestic civil engineering construction. Due to the different resources and compositions of limestone and dolomite in different places, while designing the process of the whole production line, fully consider the specifications and uses of the demand for the surrounding market, so as to provide enterprise users with reasonable lime processing equipment. According to the size of the site and the annual mining volume of dolomite, provide users with a complete, reasonable and economic processing production line.

Characteristics of active lime production line

1. Less investment and quick results.

2. Short construction period and low energy consumption.

3. Low cost, high product activity and environmental emission.

4. High efficiency, less pollution and rational utilization of resources.

5. The equipment is simple and the production line is easy to design.

Zhengzhou Bulang Machinery Technology Co., Ltd. is a large-scale active lime production equipment and process R & D base in Henan. It has advanced production technology, high-standard technical personnel and high-tech production equipment. Professional engineers are responsible for production equipment and process design. Professionalism, efficiency and perfection are the perfect interpretation of our company. Welcome to our factory for on-site investigation. You can also call our company in advance.