Product series

Zhengzhou Bulang Machinery Technology Co., Ltd

Hotline:0371-67827320

Address:No. 18, Dongfang Road, Mazhai Economic Development Zone, Erqi District, Henan, China

Phone:13523525799

Email:

Current location:Home > Products > Cement equipment - rotary kiln >

Cement equipment - rotary kiln

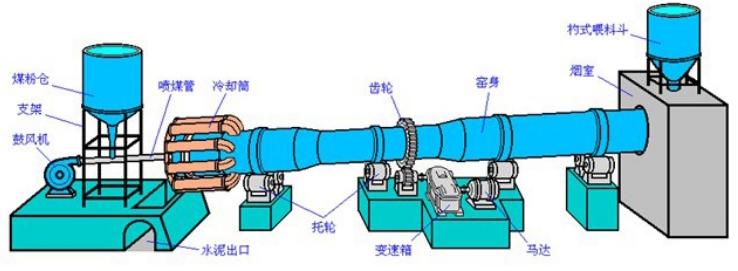

Product introduction:Rotary kiln is a new type of dry cement production line, which is mainly used for cement clinker production. The equipment consists of cylinder, supporting device, supporting device with retaining wheel, transmission device, lubrication device, movable kiln head, kiln tail sealing device, etc

Cement rotary kiln [product specification]: Φ two point five × 40m- Φ six × 95m [production capacity]: 180-10000t / D [application] cement, silicate products, new building materials, refractories, glass ceramics and other production industries. [applicable materials] limestone, cement clinker, bauxite, activated lime, aluminum hydroxide, etc Rotary kiln is a new type of dry cement production line, which is mainly used for cement clinker production. The equipment is composed of cylinder, supporting device, supporting device with retaining wheel, transmission device, lubrication device, movable kiln head, kiln tail sealing device and other components. The rotary kiln has the advantages of simple structure, reliable operation and easy automatic control in the production process.

The cement rotary kiln produced by Bulang is a common cement production equipment and cement in the cement production process. This series of rotary kilns are mainly composed of kiln shell, tire ring, thrust roller, etc.

1. Kiln shell: the thickness of the steel plate of the rotary kiln shell produced by our company is about 40mm, and there is a layer of refractory brick with a thickness of about 200mm inside. The quality of refractory brick usually directly affects the service life of rotary kiln. At the end of the kiln, there is a conical feed chamber about one meter long, so that the materials can enter the kiln more easily.

2. Tyre ring: supporting roller, bearing, tyre ring and supporting roller are all used to support the weight of the kiln. In order to reduce the heat radiation from the kiln shell to the tire ring, resulting in the high temperature of the supporting wheel, a heat insulation board is added between them to reduce the heat radiation. Rotary kiln (rotary kiln) generally has 2 to 3 groups of supporting wheels.

3. The thrust roller is the limit switch that restricts the rotary kiln (rotary kiln) from eating or eating.

Highlight advantages

|

| ||||

|

|

working principle

Pulverized coal (natural gas) burns in the rotary kiln to generate heat. The heat heats the materials through gas conduction or radiation. At the same time, with the continuous rotation of the kiln body according to the designed slope and speed, the raw materials also roll forward periodically in the kiln, so as to transport the raw materials from the feed end to the discharge end. At the same time, it is ensured that the raw materials are calcined into qualified clinker within the time they pass through the rotary kiln, so as to achieve the purpose of high yield, high quality and low consumption.

技(jì)術(shù)參數

| 産品規格 (m) |

窯體尺寸 | 産量 (t/d) |

轉速 (r/min) |

電(diàn)機(jī)功率 (kw) |

總重量 (t) |

備注 | ||

| 直徑(m) | 長(cháng)度(m) | 斜度(%) | ||||||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 | 帶立筒預熱器(qì)窯 |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 | ------ |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196.29 | ------ |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ------ |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 201.58 | 窯外分解窯 |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210.94 | ------ |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 | 窯外分解窯 |

| Φ3.0×60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 | 鋁礬土(tǔ)煅燒窯 |

| Φ3.2×50 | 3.2 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 | 窯外分解窯 |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 | 預熱發電(diàn)窯 |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 | 預熱發電(diàn)窯 |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 | 餘熱發電(diàn)窯 |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 | 預熱發電(diàn)窯 |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 | 預熱發電(diàn)窯 |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 | 預熱發電(diàn)窯 |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 | 預熱發電(diàn)窯 |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 | 預熱發電(diàn)窯 |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 | 預熱發電(diàn)窯 |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 | 預熱發電(diàn)窯 |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 | 預熱發電(diàn)窯 |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 | 預熱發電(diàn)窯 |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 | 預熱發電(diàn)窯 |